Belt conveyors MP-BC

Belt conveyors - MP-BC

Belt conveyors are typically used for transportation of solid cake from MP-DW dewatering machines, but they could be used for general transportation of powder-based materials as well.

Belt conveyor is used for transporting sludge cake from MP-DW dewatering screw press. The use of conveyor is particularly found when placing a dewatering machine inside the building, while sludge transport containers are usually located outdoors for better handling. The conveyor can be used up to an inclination of 18 °, thus a certain elevation can be overcome and the dewatering machine does not have to be positioned above the container itself.

The conveyors are delivered on pedestal with lockable wheels, so they do not need to be fixed to ground on one permanent position. Conveyor can be used mobile as needed - for example, using multiple containers for sludge cake or possibility of storing the conveyor after dewatering and space saving.

Unlike screw conveyors, belt conveyors are considerably lighter, cheaper, and more economical in terms of power consumption, no heating is necessary for the winter time, maintenance and service are easy to do, and there is no risk of damaging the bearings if sludge cake is too wet and comes into the conveyor.

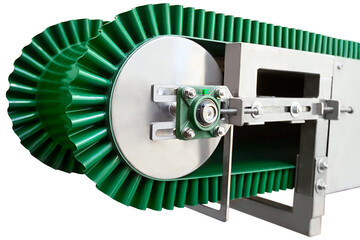

Belts have so-called waveguides welded on the side of belt. This keeps the transported material on the belt and prevents leaking of material to the side. This type of construction prevents tightness issues on borderline of belt and frame for other types of belt conveyors.

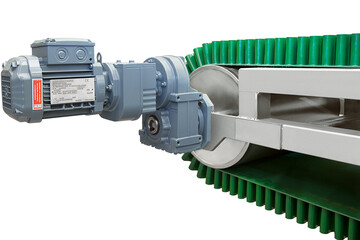

The SEW Eurodrive gearbox with front transmission is used to drive the conveyor. The cylinders are mounted in roller bearings.

Belt conveyors - MP-BC

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h