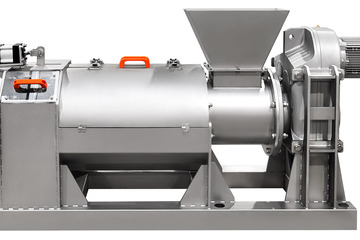

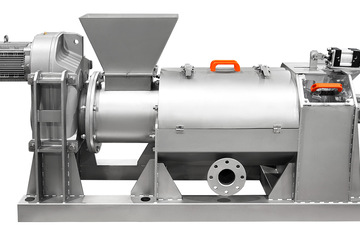

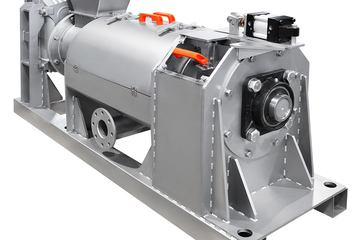

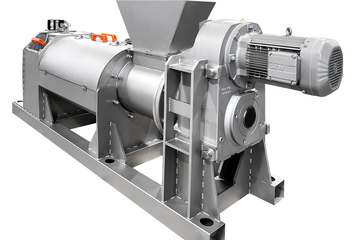

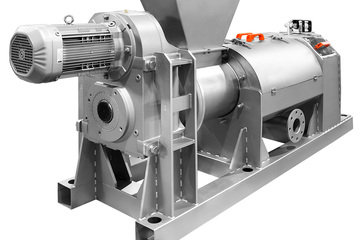

Screw separator MP-SS

Screw separator - MP-SS

The screw separator mechanically separates water from solids without the use of flocculant, unlike the MP-DW screw press.

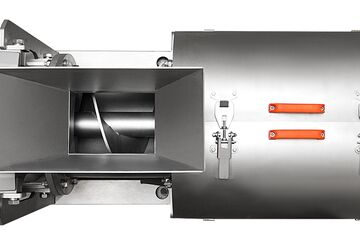

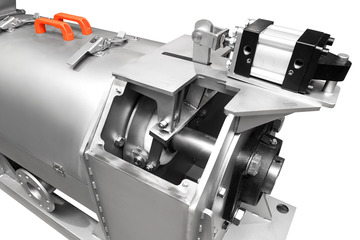

The machine processes sludge in a dewatering mechanism, which consists of a screw shaft surrounded by a wedge filter. The dewatered sludge is gradually compressed inside the mechanism, allowing the filtrate to pass through the wedge filter while the dry sludge exits at the pressure plate (at the end of the shaft).

Main benefits of MP-SS:

- Low operating costs

- Robust and compact design

- Versatility across different industries

- Optional size of wedge filter gaps

Screw separator - MP-SS

Size calculator

Please input desired hydraulic flow and suspended solids content. Our calculator will suggest you optimum size of machine...

- WT primary sludge - raw sludge from activation (ČOV – surový kal z aktivace): 0,5–1%

- WWT secondary sludge - after final settling tank (ČOV – stabilizovaný, zahuštěný kal): 1,5–4 %

- Sludge from DAF (Kal z flotace): 2–4 %

- Biogas station sludges (Kaly z produkce bioplynu): 4–6 %

- Grease traps, oil separation (Lapáky tuku, olejové aplikace): 4-6%

Capacity of MP-DW - dry material flow per hour :

- MP-DW-131: 10 kg/h

- MP-DW-201: 30 kg/h

- MP-DW-301: 60 kg/h

- MP-DW-302: 120 kg/h

- MP-DW-401: 140 kg/h

- MP-DW-402: 280 kg/h

- MP-DW-403: 420 kg/h